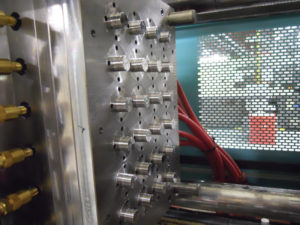

Mold-Rite Plastics, Inc. was evaluating whether to refurbish or replace an old 48-cavity unscrewing mold that was manufacturing a viable and in-demand 24mm cap.

After learning about DT Collapsible Cores, Mold-Rite was able to do the math and see the cost advantages of replacing the 20-year-old mold with one utilizing new technology that would run faster and simpler, with less maintenance and downtime. The results and cost savings were dramatic:

Roehr President Dave Helenius said, “Mold-Rite is able to run the mold faster and in a smaller machine, decreasing the cost per thousand parts by 30%. Additionally, the cost of yearly maintenance and quality decreased 46% with the DT Core mold. This is significant.”

“If we plug Mold-Rite’s data into our online Cost Savings Calculator, capital cost savings are notable,” Helenius adds. “By converting to a simpler DT Core mold, Mold- Rite reduced their overall mold build costs by 60%.”

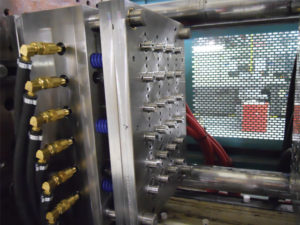

“The technical support was excellent” commented the senior design engineer and tool room manager at Mold- Rite. “We learned proper handling, disassembly and assembly of the cores, as well as installation of the cores into the mold base. Everything went very smoothly and the overall results speak for themselves.”